Your cart is currently empty!

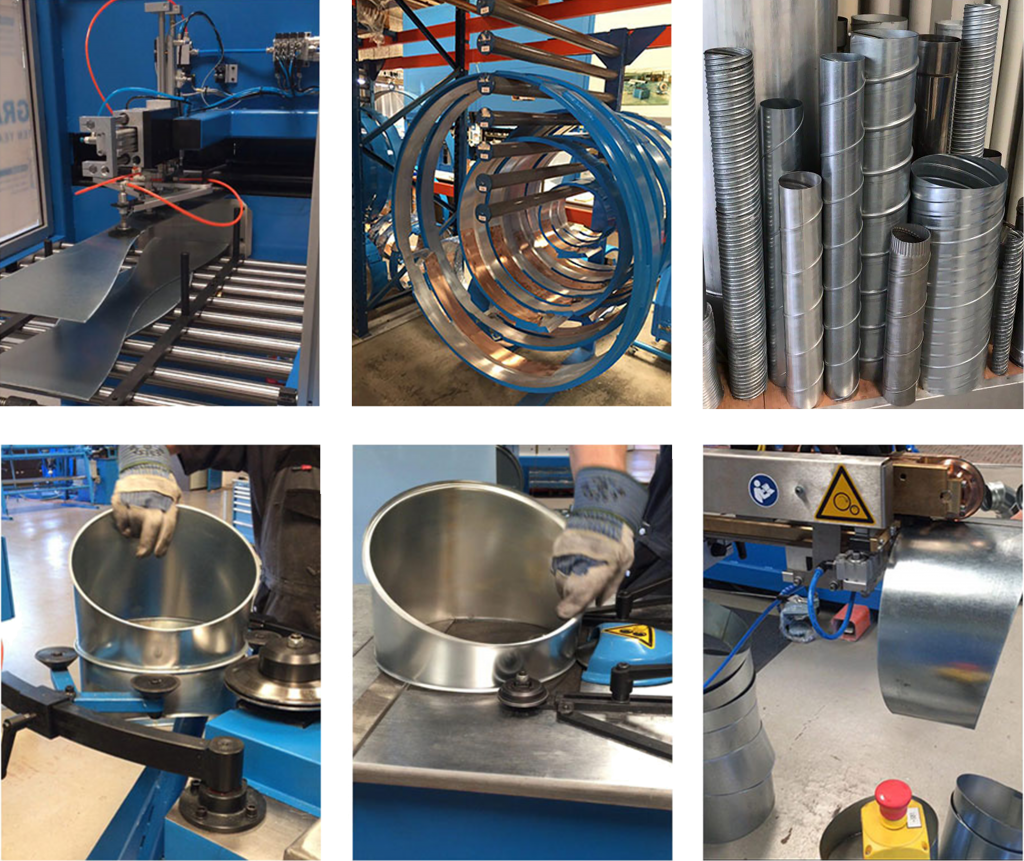

Galvanized Spiral Air Duct

The spiral airduct is a type of round air transmission duct that can be produced from 3 to 72 inch in diameter using galvanized, aluminum or stainless steel strips. These ducts can be produced with thicknesses of 26, 24, 22, 20 and 18 Gauge or custom with higher thicknesses, according to the desired project. Dimensions…

Free Shipping

Supportive short description

in max 2 lines

Easy Return

Supportive short description in max 2 lines

Money Back Guaranty

Supportive short description in max 2 lines

Description

The spiral airduct is a type of round air transmission duct that can be produced from 3 to 72 inch in diameter using galvanized, aluminum or stainless steel strips. These ducts can be produced with thicknesses of 26, 24, 22, 20 and 18 Gauge or custom with higher thicknesses, according to the desired project.

Dimensions and sizes

The suggested thickness according to the diameter is as following:

| Size | 4″ – 22″ | 24″ – 30″ | 32″ – 36″ | 38″ – 50″ | 52″ – 60″ |

| Gauge | 26 | 24 | 22 | 20 | 18 |

Nowadays, due to reasons such as simple installation and beautiful and modern appearance, high strength and durability, low energy losses, lower air pressure drop compared to square ducts, increased speed of production and delivery due to common connections, the ability to pre-produce and store channels to provide services. Fast to the customers, the demand to use the spiral channel has increased a lot.

Therefore, to achieve the quality and accuracy in accordance with the valid standards of construction, design and production of parts, the Ductivo brand has used the relevant software and modern European machines to provide the best services to the customers in the shortest time.

Features of galvanized spiral Airduct

- Due to common connections and pre-production capabilities, delivery times are minimized.

- Due to the smaller side surface compared to the square channel, it has less energy loss.

- Based on the type of application, they are made of galvanized sheet, aluminum or steel.

- Compared to round channels with longitudinal seam, it has higher strength.

- Compared to the square duct, it creates less noise and pressure drop.

- Beautiful and modern appearance for environments with exposed design

- Correct distribution of air and uniform flow

- Less need for support and flange

- Quick and easy production and installation

- Ease of insulation

- No air leakage

Galvanized spiral airduct structure

The way Ductivo spiral airductl is made is in such a way that the sheet that is produced with that duct rotates in the form of a spiral seam around the axis of the round duct and creates a ridge on the duct from the outside, which makes it stronger than round airducts. It is normal with a longitudinal seam and similar thickness.

Although the surface of the spiral air duct has a bump on the outside, it is completely smooth on the inside and does not cause any pressure drop along the path of air or other fluid movement.

The presence of Spiral Seam in Ductivo’s spiral airducts creates very high strength in the duct and minimizes duct leakage by creating proper air sealing. To increase the strength, ridges can be added around the duct. As a result, the duct can be produced lighter, cheaper and with less thickness than a round airductl with a longitudinal seam or an equivalent square airduct.

Double Wall Insulated Spiral duct

Double Wall (or Dual Wall) insulated spiral duct provides unparalleled thermal insulation and noise reduction capabilities. This method stands out as the ultimate choice for insulating spiral ducts due to its unmatched reliability, long-lasting durability, and permanent effectiveness.

Consisting of two concentric spiral ducts with different diameters, the space between them is filled with insulation, often utilizing fiberglass. This construction results in a dual wall insulated spiral duct that boasts near-impenetrable airtightness. Furthermore, the insulation is safeguarded against the most prevalent causes of deterioration: damage during on-site work, erosion caused by high-pressure environments, turbulence in airflow, and the formation of condensation.

The inclusion of factory-installed insulation eliminates the need for time-consuming and labor-intensive installation procedures at the actual job site.

The duct liner possesses the capability to absorb a wide range of equipment and airflow-generated noises. Constructed with glass fiber, it captures and disperses noise within its fiber matrix. Instead of transmitting noise, it ensures the conveyance of clean air. Additionally, it functions as a thermal insulator, contributing to energy conservation.

Furthermore, the utilization of metal duct enhances fire safety due to its noncombustible properties. For situations demanding high-temperature endurance, mineral wool insulation is available, capable of withstanding temperatures up to 1000º F.

When aiming for noise reduction, the inner wall of the dual wall spiral duct is strategically perforated with numerous 3/32″ holes spaced at 3/16″ intervals. These perforations effectively redirect system noise, flanking noise, and cross-talk noise into the insulation layer where it is absorbed. To prevent insulation particles from entering the airflow, an acrylic binding agent is infused within the insulation. To maintain indoor air quality, antimicrobial agents are commonly integrated to prevent the growth of mold and bacteria.

Nearly all the fittings compatible with single wall spiral ducts can also be used with dual wall spiral ducts. This grants designers the same flexibility they enjoy with a single wall system. Just like with single wall spiral ducts, dual wall fittings feature a male design, while dual wall ducts have a female design. This design ensures a straightforward, efficient, and cost-effective slip-joint installation process that proves especially suitable for light commercial applications. For scenarios involving higher pressure and larger diameters, various economical and proven flange connection methods are available. (For detailed installation instructions, refer to the Installation tab above.)

Additional information

| Diameter | 3 Inch, 4 Inch, 5 Inch, 6 Inch, 7 Inch, 8 Inch, 9 Inch, 10 Inch, 11 Inch, 12 Inch, 13 Inch, 14 Inch, 15 Inch, 16 Inch, 17 Inch, 18 Inch, 20 Inch, 22 Inch, 24 Inch, 26 Inch, 28 Inch, 30 Inch, 32 Inch, 36 Inch, 40 Inch, 44 Inch, 48 Inch, 56 Inch, 64 Inch, 80 Inch, 72 Inch |

|---|---|

| Thickness | 26 Gauge, 24 Gauge, 22 Gauge, 20 Gauge, 18 Gauge |

| Lenght | 5 ft, 10 ft |

| Material | Galvanized, Aluminium, Stainless Steel |

| Color | Galvanized Finish, White, Gray, Matt Black, Semi Matt Black, Shiny Black, Cream, Yellow |

Reviews

There are no reviews yet.